This setup allows for a light print head and 3D printing at higher speeds without encountering print issues like ghosting and ringing The filament is then fed through a PTFE tube from the cold to the hot end.

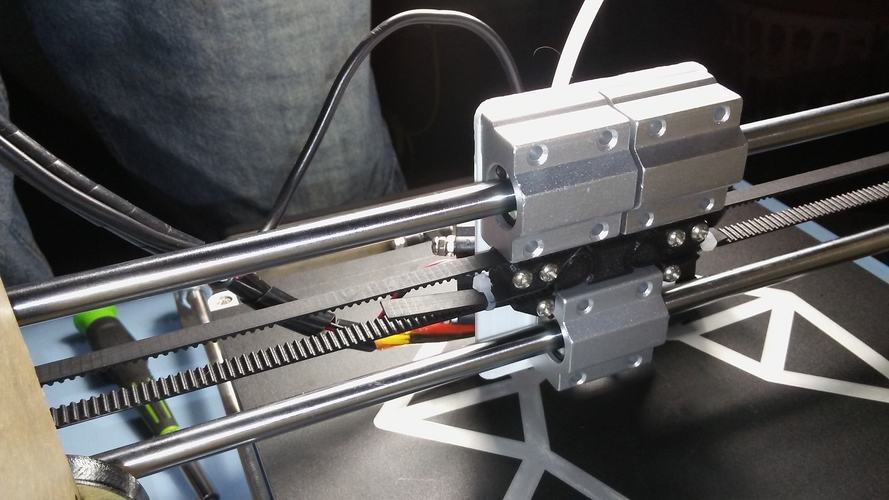

3D Printer Extruder Typesīowden extruders have their cold end mounted onto the 3D printer’s frame instead of above the hot end. The best 3D printer extruders will let you reliably 3D print at high speeds with various materials without affecting the print quality. The 3D printer filament is then melted by the heat produced by the heater and pushed out through a nozzle where it solidifies to create your 3D printed object. The 3D printer filament is pushed through the heat break by the cold end until it reaches the heater block. It consists of various components, like the heat break, heater block, and nozzle. The majority of the 3D printer extruders utilize a system of gears and a pulley combined with a spring-loaded arm to accomplish this function. The cold end consists of a mechanism designed to pull your filament from one end and push it out of another while firmly grasping it. The first group of components is called the cold end. The extruder consists of various grouped parts. considering the reputation and quality of E3D this extruder must work out of the box unless you have received damaged components.A 3D printer extruder is the part of an FDM 3D printer that melts and pushes out plastic filament to create the three-dimensional object. This should not be a problem for such a priced and tested extruder system, i.e. In troubleshooting this problem it is best to increase the current to the stepper close to the upper side of the specifications of the stepper and see if the knocking sounds disappear. If the filament skips back while the gears are in place the tension/grip to the filament needs to be increased. If the gears loose position, this means that the stepper is not powerful enough to push it through, this means that more current or a more powerful stepper is required (the latter option is due to the design of the extruder not possible). My own designed 2.85 mm filament, 1:4 speed reducing belt driven extruders make clicking sounds while extruding (independent of the layer height), I have verified that no steps are lost and the printer extrudes exactly the requested amount of filament (2.85 mm filament requires a lot more pressure for the same nozzle size, the noise is coming from inside of the metal Bulldog housing, not the stepper adjacent, it is not stepper nor filament skipping noise).Ī clicking sound in combination with gears losing position as you describe (or filament skipping back) does mean that the pressure in the nozzle is too big for the extruder to push it through. I feel like I checked all the steps and I'm just missing something.Ī knocking or clicking sound does not imply you have a problem, it implies that you could have a problem it can be the characteristic of the extruder. I'm just not sure what could be wrong here. (I've read somewhere that the Hemera motor wants 800 to 1000 mA)

The sound is kind of loud, but that's most likely the resonance in the machine than a symptom, stating it nonetheless. Z > 1 mm when I finally decided to ask this question. The first time I noticed it, it was printing the cabin of Benchy. The sound happens at varying heights and not just the first layer. I'm pretty sure that it's not skipping steps. It looks to me that the motor is stuck or frozen. I also see that the gears move one step back and forth. I did do a cold pull the other day.īut I've noticed that my extruder is making a knocking sound, as if someone was gently rapping on my chamber door. Once I do get the plastic in, it quickly and easily pushes through and spits out of the nozzle so I think that my nozzle isn't clogged. Maybe it's due to the Hemera's tight tolerances or due to a misalignment in the hot end, I'm not sure yet. Though, I do struggle getting the filament into the nozzle. I cleared out the clog and I'm able to feed plastic through after disengaging the idler arm. I assumed it was a clogged nozzle and possibly heat creep (because I was a dummy and used my old, bowden retraction settings on my new, direct extruder). Then I noticed that I was struggling with getting the PLA filament to feed into the nozzle.

My original thought was that my E-steps were off (because they were) but I solved that and I still have a problem. Every time I go to print something the printer stops pushing plastic out and usually the motor makes a knocking sound. I've been trying to print anything for the past few days.

0 kommentar(er)

0 kommentar(er)